Innovation with Intention: Spartech's Innovation Center Empowers Breakthroughs in Product Formulation

Innovation with Intention: Spartech's Innovation Center Empowers Breakthroughs in Product Formulation

This blog is the first of two in our Innovation Center Spotlight Series; keep an eye out for the next one—which will focus on product development and testing for use in controlled environments.

At Spartech, we believe in Innovation with Intention.

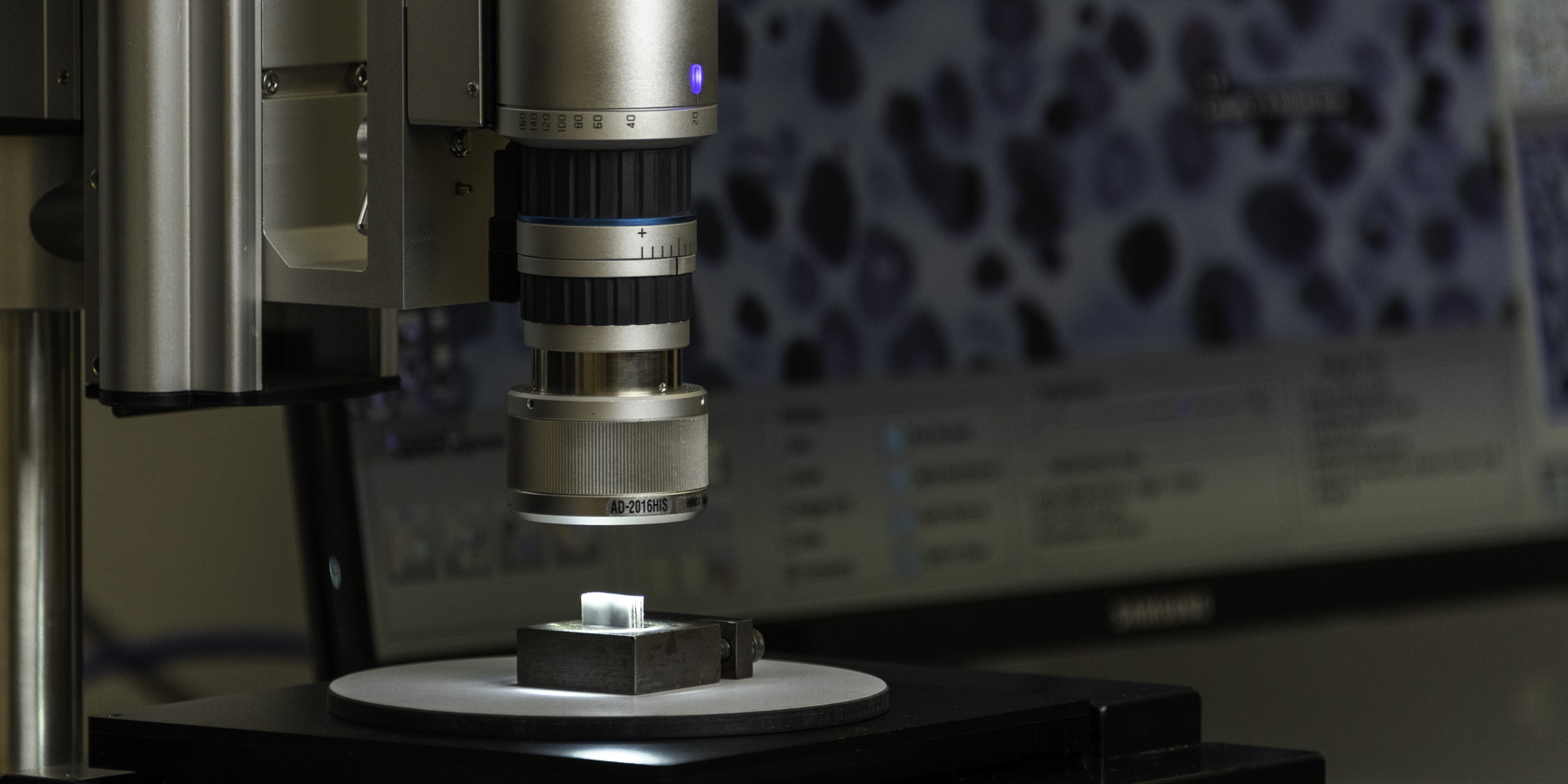

Our world-class Innovation Center, a 90,000-square-foot facility devoted exclusively to product development, testing, and formulation, stands out as a beacon of innovation and problem-solving. Whether customers are looking to maximize sustainability, increase functionality, reduce price—or develop a new solution that combines all three—the experts at our Innovation Center guide the process to help bring products to market quickly and efficiently.

Below are examples of the daily challenges we help customers solve at our Innovation Center.

Customer Challenge #1: Test specific performance attributes.

We often receive customer requests to help them expand or modify product specs. In certain situations, customers may seek a range of results from a product line. With the Innovation Center's product formulation and testing all under one roof, we can quickly evaluate a customer's existing product, define how it fits into the marketplace, recommend improvements, and reduce the customer's go-to-market lead time.

John Vandeven, Chief Technology Officer, explains, "With our capabilities, we can evaluate how market expectations compare to the customer's baseline product and identify gaps. We might say, 'We have a good platform internally; now, let's look at the benchmark of where you want to be competitively,' and advise how the product can best be rebuilt or formulated."

We accelerate the development process and help customers meet or exceed market expectations for their products by removing the need to start at square one, making the process more efficient and faster.

Customer Challenge #2: Understand complex formulation performance.

A significant aspect of our work at the Innovation Center involves testing and validating proposed product formulations to ensure they meet specifications and performance attributes. We also help analyze complex formulation structures, such as multi-layer components featuring adhesives or backers.

These components may fall outside the materials we supply, but analyzing them helps us understand their basic chemistry and how they influence the overall performance of the finished structure.

For example, last year, our engineers created and customized a multi-layer PreservaPak® solution for a Food & Beverage customer. We utilized new, food-safe materials for the inner and outer layers of the single-use container and an environmentally friendly, recycled material on the interior. The solution we developed accomplished the customer's goals for both material cost and sustainability.

Testing is critical for assessing potential impacts on performance and regulatory compliance when introducing additional adhesives, paints, films, or other elements. It all comes down to grasping the entire structure of the chemistry—what our product brings to the table and how it works with other materials. We're here to help customers stay compliant and meet their goals by accelerating their processes and shortening their turnaround times.

Customer Challenge #3: Serve as an outsource R&D partner to bring a new product to market.

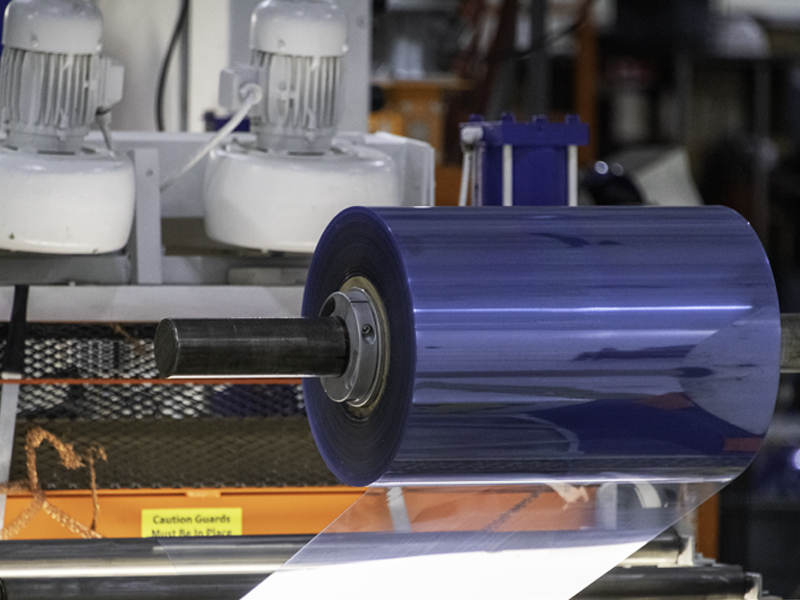

Most customers don't have an in-house R&D team to bring new products to market. Spartech not only has all these experts under one roof in our Innovation Center, but we also offer a range of tools and processes for polymer solutions, which helps avoid design limitations. We maintain a polymer-agnostic approach that allows us to develop solutions across a broad spectrum, framing up the right combinations of polymers, layering, and more.

Our process starts with either a remote meeting or, preferably, an in-person on-site meeting at the Innovation Center. We invite customer team members from commercial or technical channels depending on how their organization is structured. During this meeting, we engage in a needs analysis, ensuring we understand what the customer seeks in a solution.

Next, we work to outline an idea and align on a path forward with the customer as we formulate a solution. At this point, we pull in our engineering team, who will guide the project toward commercialization. Then, we create on to three formulations and swiftly move to prototyping, using just 150-200lbs. of material. This minimal investment enables us to migrate from small lab lines to full-size extrusion equipment, streamlining and speeding up the entire process.

"For example, we recently conducted extrusion trials on day 1, forming trials on day 4, and received all testing results by day 10-significantly faster than traditional timelines that can span months," explained Vandeven.

Customer Challenge #4: Bring a product sample to life.

Spartech's Innovation Center is built for versatility and is equipped with a wide array of polymer processing capabilities, including multi-layer extrusion technology. We're known for our fast turnaround in creating samples and prototypes; in fact, a customer walked in the door in December with a high-level concept, and by early March, they're tracking towards their final qualification trial.

When we produce samples, we provide visually satisfying, lab-scale parts that customers can touch and feel, providing a more tangible representation of the process and product. This tactile experience makes it easier to engage with the production process and envision solutions, especially when the materials undergo thermoforming as a later step, bringing dimension and volume to the sample. We can also work with our customers' tooling so they can utilize our equipment to produce a sample run or prototype.

"Running our Innovation Center at this scale enables customers to visualize the end product more effectively compared to merely seeing a 2-inch square sample," said Evelyn Xavier, Senior Chemist at Spartech.

Our Innovation Center is all about helping you right from the start. We'd love to talk if you're thinking about creating something new or improving your current product. Contact us to learn more.

March 22, 2024